In-Depth II: Grand Seiko Kodo Constant-Force Tourbillon SLGT003

All about the technical details and accuracy.

Having delved into the origins, concept, and design of the Grand Seiko Kodo Constant-Force Tourbillon SLGT003, we now turn to the granularity of its technical qualities. The Kodo is first and foremost a chronometer in the vein of the watches that lay behind the founding of Grand Seiko (GS).

A brand focused on precision timekeeping since its establishment in 1960, the opening act of GS in its first decade was competing in observatory chronometer trials at Neuchatel and Geneva – and winning, much to the horror of the Swiss. Several decades later the brand is still pursuing perfect accuracy in both mechanical, quartz, and hybrid formats, most notably with the novel Spring Drive.

The Kodo powered by the cal. 9ST1 is the latest, and arguably greatest, endeavour in chronometric precision from GS. But it is like no GS that has come before it. Rather than rely on modern technology and materials, the Kodo instead revisits traditional mechanical solutions, namely as the constant-force mechanism and tourbillon. Combining the two in a wristwatch mark a milestone for GS, or any Japanese watchmaker for that matter.

To understand the mechanical systems within the Kodo, we must first understand the fundamental challenges in precision timekeeping. The factors that influence precision fall into two categories, the first related to the barrel or energy supply, and the second, gravity’s effect on the balance or oscillator.

Energy challenges

The barrel is the source of energy in a conventional mechanical movement. It’s essentially a cylinder that houses the mainspring, which is a coiled length of metal that stores energy when wound up tightly. While it is an effective energy source, the mainspring nevertheless has a weakness: it delivers steadily declining torque as it winds down and the coils of the spring slacken.

The lower torque means a less energy for the oscillator, resulting in a shorter swing of the balance, more precisely described as a drop in amplitude. With a shorter distance travelled, the time needed for the balance to complete an oscillation diminishes, so the movement will beat faster or at a higher frequency.

That said, readers who have come across the term isochronism – the property of maintaining the same frequency despite changing amplitude – might wonder why it doesn’t apply here. While an ordinary balance largely operates according to this phenomenon, it does not do so perfectly because of inconsistencies in material and fabrication.

That is why watches can keep relatively good time with diminishing torque, varying only seconds each day for instance, but never perfectly. Modern materials science and manufacturing technology does help with maintain isochronism, but such innovations are invisible to the observer.

Traditional solutions of the sort that watch enthusiasts revere focus instead on addressing the root cause of the problem, which is the variation in torque of the mainspring. This approach certainly requires mechanical intervention, which is where constant-force mechanisms come in.

There are two types of constant-force mechanism. The first works directly with the power supply, like a fusee and chain, stack freed, or simply a stop-work, while the second sits along the going train, such as a remontoir. The former evens out the torque delivered by the barrel regardless of the mainspring’s state of wind, while the latter relies on a buffer spring to store and deliver small, even portions of energy to the balance at fixed intervals.

An example from Swiss watchmaking that incorporates both types of constant force mechanisms, a chain and fusee as well as a remontoir, the Ferdinand Berthoud FB 2RE

While the chain and fusee is magnificent, it is bulky and inevitably occupies half the movement. In fact, it takes up so much space that it only made it into a wristwatch about three decades ago.

In contrast, the remontoir is a more elegant solution that’s compact and more effective. Controlling the power flow right before the balance ensures all errors that occur along the gear train are dealt with, which is why the late George Daniels described it as “by far the best method of smoothing the power supply” in his treatise Watchmaking.

Unsurprisingly given GS’s penchant for refined engineering, the Kodo is equipped with a remontoir, specifically one that’s integrated into the tourbillon regulator, an unorthodox construction that we explained below.

The twin mainsprings of the Kodo are visible below the sub-dial for the time – together they provide more stable torque than a single barrel, though not with the exactitude of a chain and fusee

Newton’s Law

The second primary source of errors in a mechanical movement is gravity as it interferes with the oscillation of a balance depending to a degree that depends on the position of the watch. This exacerbates the inherent imperfections of a balance assembly that arise from manufacturing or assembly oversights.

As we have already discussed this topic at at-length, we will skip the problems and instead cover only the solutions. One of the best-known is the centuries-old trick of constantly changing the position of the balance average out such errors, otherwise known as the tourbillon.

The Kodo incorporates not one but two systems to tackle inaccuracy, a remontoir inside a tourbillon. Both sit on the same axis with power flowing from the mainspring to the remontoir and then the tourbillon.

One of the twin barrels inside the Kodo. Image – Grand Seiko

The Kodo is equipped with twin barrels that operate in parallel, meaning both unwind simultaneously. This set-up typically delivers more energy per period of time than a single mainspring.

According to Mr Kawauchiya, double barrels set up in parallel typically have shorter running times than the twin barrels arranged in series. But the twin barrels in the cal. 9ST1, he adds, are notable for offering a relatively long running time of 72 hours.

As an aside, why do the best modern chronometers from the likes of Grand Seiko and Omega keep excellent time without any fancy, traditional mechanisms? The Grand Seiko Standard that entry-level mechanical GS watches has to meet is within +5.0/-3.0 seconds a day – and these are watches with no compilations that cost under US$10,000.

Keeping good time affordably, the 9S63 movement found in GS models priced around US$7,500

One reason is that the movements are simple and only require relatively low tolerance in fabrication and assembly, which allows for more efficient production while maintaining quality.

Another factor is the science of modelling and manufacturing has improved enough that impressive accuracy is possible with a standard Swiss-lever construction.

Finally, such everyday watches are typically automatic, allowing the mainspring to remain almost fully wound at all times, eliminating the decline in torque seen in a manual-wind watch that’s only wound every day or two.

Still, anachronistic technology makes for an impressive object, which is exactly what the Kodo is.

One of the rare few

While tourbillon wristwatches are now common, few are equipped with a constant-force mechanism and even fewer have both a tourbillon and constant-force mechanism.

Arguably the most famous example equipped with both is the F.P. Journe Tourbillon Remontoir d’Egalite. Mr Journe’s concise invention utilises a thin blade spring to store and release energy to the tourbillon cage every second.

But there are also other interpretations of the concept that are more elaborate and perhaps more elegant, most notably integrating the remontoir into the tourbillon. Past examples include the magnificent Double-Wheel Remontoir Tourbillon pocket watch made by Derek Pratt in 1997, which has not one but two remontoir escapements in the tourbillon. More recently, and more usual coming from a mainstream brand, is the IWC Portugieser Sidérale Scafusia that combines a constant-force tourbillon with a variety of astronomical complications.

Finally there’s the Andreas Strehler Trans-Axial Tourbillon that most closely resembles the Kodo in its approach. Both rely on a remontoir that’s not only within the tourbillon cage, but also shares the axis of the tourbillon, resulting in an impressive construction that’s vertically symmetrical.

The F.P. Journe remontoir with its thin blade spring

The twin escape wheels and remontoir of the Derek Pratt pocket watch, which uses spiral remontoir spring instead of linear blade spring as found in the F.P. Journe. Image – Timothy Treffry

Why Kodo

The watches mentioned above show that there are precedents to the Kodo, albeit very, very few. From a historical perspective, the Kodo might not be as significant as the Derek Pratt pocket watch – yet since GS is still establishing itself as a serious maker of complications – but its fundamentals are truly excellent.

From the perspective of the brand itself, the Kodo is a milestone for GS and indeed historically significant for the brand. It boasts multiple firsts for GS: tourbillon, constant-force escapement, as well as open-worked movement. But the Kodo is not just regurgitating ideas from the past. Instead it Kodo manages to distinguish itself thanks to several innovations not found in other watches.

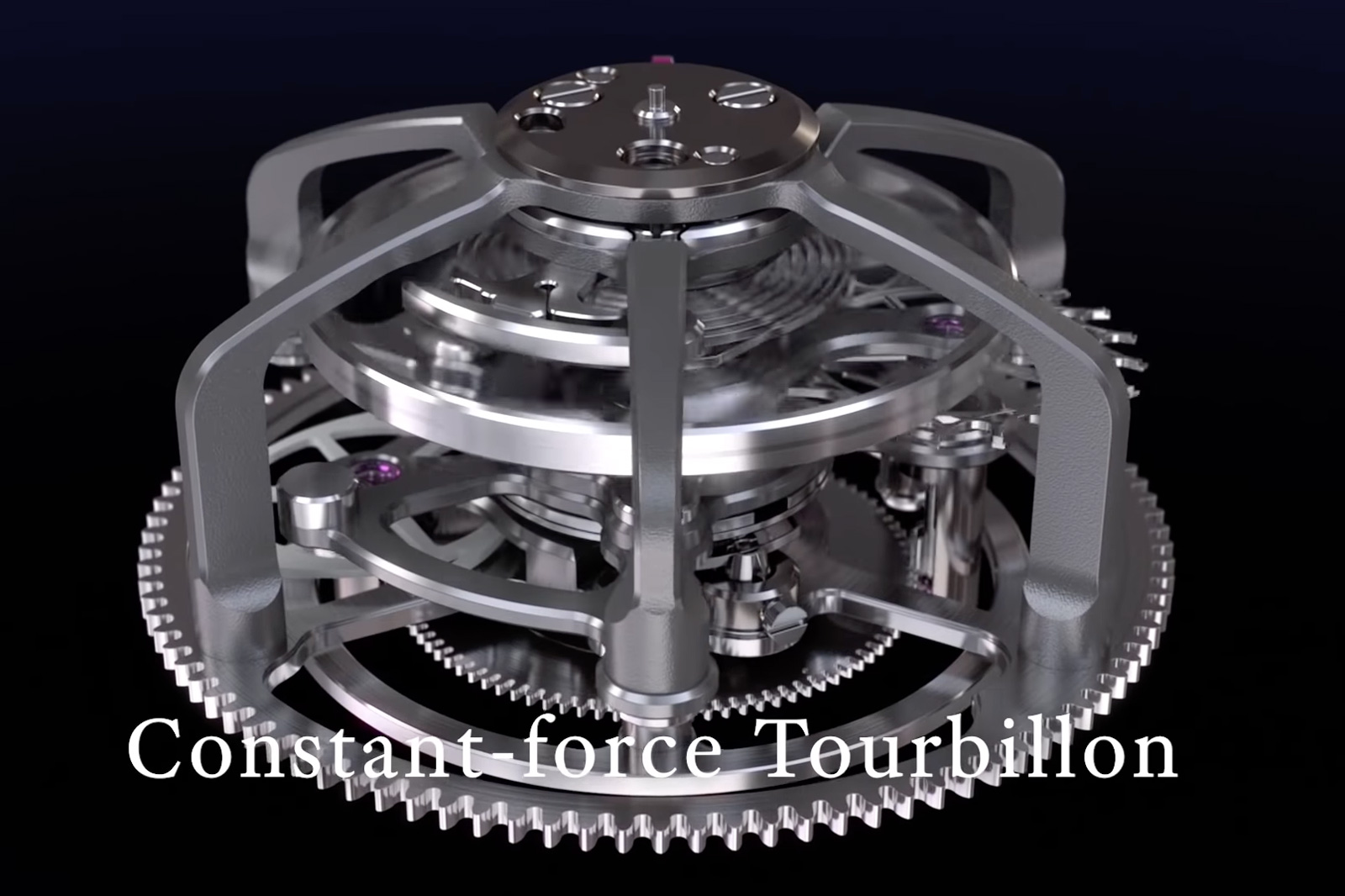

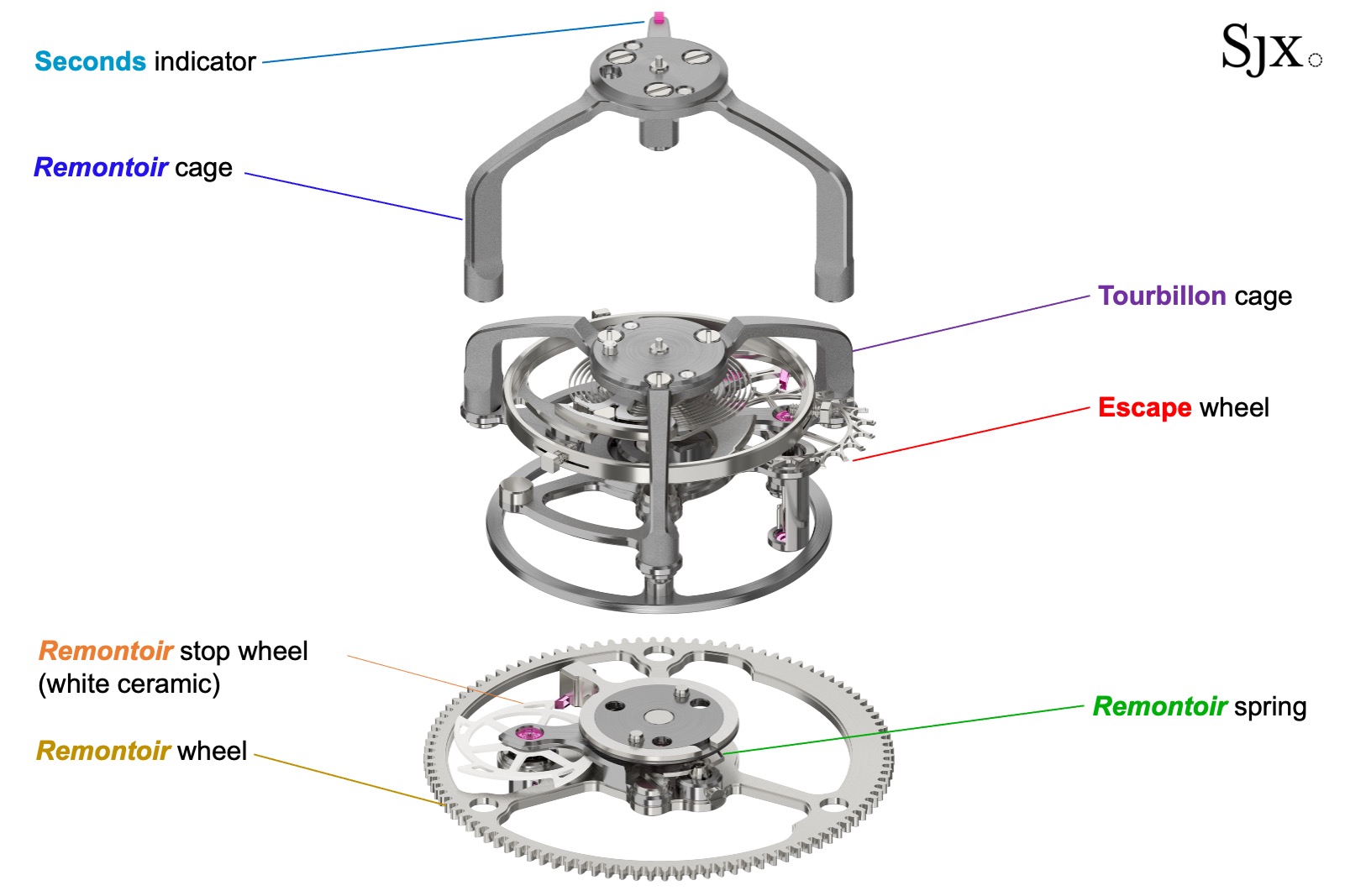

The first innovation are the nested, double carriages, one each for the tourbillon and remontoir. Innermost is the tourbillon cage, which is conventional in function and rotates in tiny steps as expected, eight steps a second to be precise.

But the remontoir cage is unusual. It encloses the tourbillon cage and advances once every second, so it doubles up as a deadbeat seconds indicator. But it is definitely more impressive visually than a seconds hand because the entire three-armed cage springs forward each second accompanied by the confident tick of the remontoir wheel.

An extremely complex construction with a triple three-arm set up (for a total of nine arms): the outermost trio forms the three-armed bridge, and the innermost set of arms is the tourbillon cage, while the remontoir cage is sandwiched between the two

The second innovation is actually hinted at by its name, 鼓動 or kodo, which is “heartbeat” in Japanese. As with all remontoirs, the remontoir in the Kodo creates a ticking sound similar to the tick-tock of an escapement when it releases every second.

But the cal. 9ST1 actually emits two perfectly synchronised pulses at a steady pace – these arise from the remontoir and escapement respectively – creating a rhythmic beat. The fact that the escapement beats at the relatively high frequency of 4 Hz is even more impressive, since most tourbillon movements run at a lower frequency to minimise energy consumption.

Synchronising the beats might seem like a simple task but it is a bona fide feat of micro-engineering since any inconsistency in the frequency will result in the rhythm slightly, but noticeably, out of sync. The perfect rhythm demonstrates one of the Kodo’s strength, an ultra-precise construction made possible by parts fabricated with cutting-edge technology such as ultraviolet lithography (UV-LIGA).

The high level of technology used in manufacturing the movement parts set the Kodo apart from comparably complicated timepieces that are often made the traditional way – and this is a good thing, especially when considering the subsequently artisanal decoration of the cal. 9ST1.

“I realised in the early prototype stage that it was not easy to make the escapement and remontoir tick together in an exact 16th note rhythm,” explains Takuma Kawauchiya, the designer of cal. 9ST1, “Slight eccentricities of the gears and their axes, or clearances between the axis and jewel holes would cause the constant force, which should rotate once for every eight times the escapements vibrates, to instead rotate once every seven or nine times instead, making it difficult to hear a clean 16th beat.”

The solution, says Mr Kawauchiya, is a stopper as well as extremely precise tolerances. “The stopper slides over the small teeth of the stop wheel eight times, and to ensure that the stop wheel and stopper disengage exactly on the eighth time required strict tolerances for the parts would not be required in the mass production of normal movements.”

Putting it together, however, is a painstaking process. “During final assembly, the movement is placed in a quiet room with no one else present and I listen to the ticking for one minute,” says Mr Kawauchiya, “If there is even one inaccurate beat, the stopper position is adjusted slightly, and I continue listening until a clean 16th beat is achieved.”

“Rotating the stopper is a painstaking process that can damage the parts of the carriage, but the joy of overcoming this risk and achieving a beautiful 16th note is exceptional,” adds Mr Kawauchiya with pride.

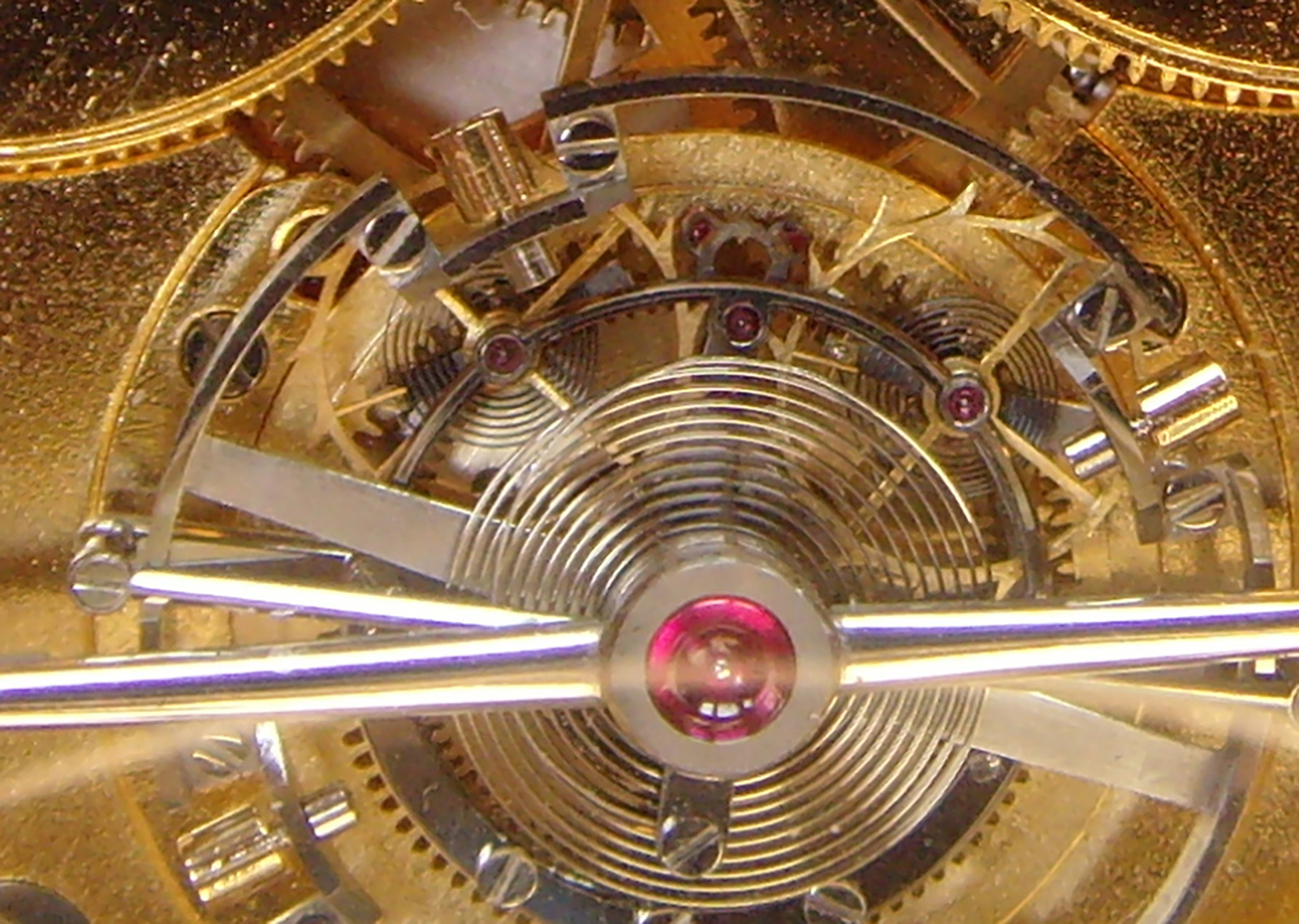

The balance wheel of the Kodo. Image – Grand Seiko

Two halves

Mechanical complexity aside, the Kodo has a beautifully symmetrical movement, as is often the case for tourbillon movements with a constant force mechanism.

The cal. 9ST1 is divided into two halves with the vertical line of symmetry running straight through the dial at 12 o’clock and the constant-force tourbillon at six o’clock. Each half houses a barrel, with each barrel accompanied by a different but visually comparable set of gears, namely planetary gears for the power reserve mechanism on the left, and intermediate wheels for time setting on the right.

According to Mr Kawauchiya, the symmetrical arrangement of the wheel train layout was, unsurprisingly, a deliberate choice of the development team from the start. But the positions of the gears serve another purpose.

“We also wanted to balance the appearance of the complex, multi-layered structure of the constant-force tourbillon carriage… by giving a multi-layered structure to the barrel as well,” explains Mr Kawauchiya, “After much consideration of what to layer, we came to the conclusion that it would be a planetary train for the power reserve mechanism and the intermediate wheels for time setting.”

“For me, a three-dimensional effect of a movement is one of the major attractions of mechanical watches and I believe looking at a pocket watch is one of those joys. However, it is quite a difficult task to create the three-dimensional looks of a pocket watch in a wristwatch,” says Mr Kawauchiya.

“In order to achieve this, we created height differences between the gears in the power reserve train… while the gears have chamfered spokes and teeth to prevent them from looking thin and monotonous, and even the MEMS gears [made via LIGA] have minute steps in the spokes to create a three-dimensional effect,” He continues, “That kept the overall thickness of the movement as thin as possible, while creating as much of a three-dimensional effect as possible within that limited thickness.”

Overview of the constant-force tourbillon

The cal. 9ST1 of the Kodo is certainly an impressive and complicated construction, and one with few peers. But each it operates on the traditional principles, so it is most easily understood one section at a time.

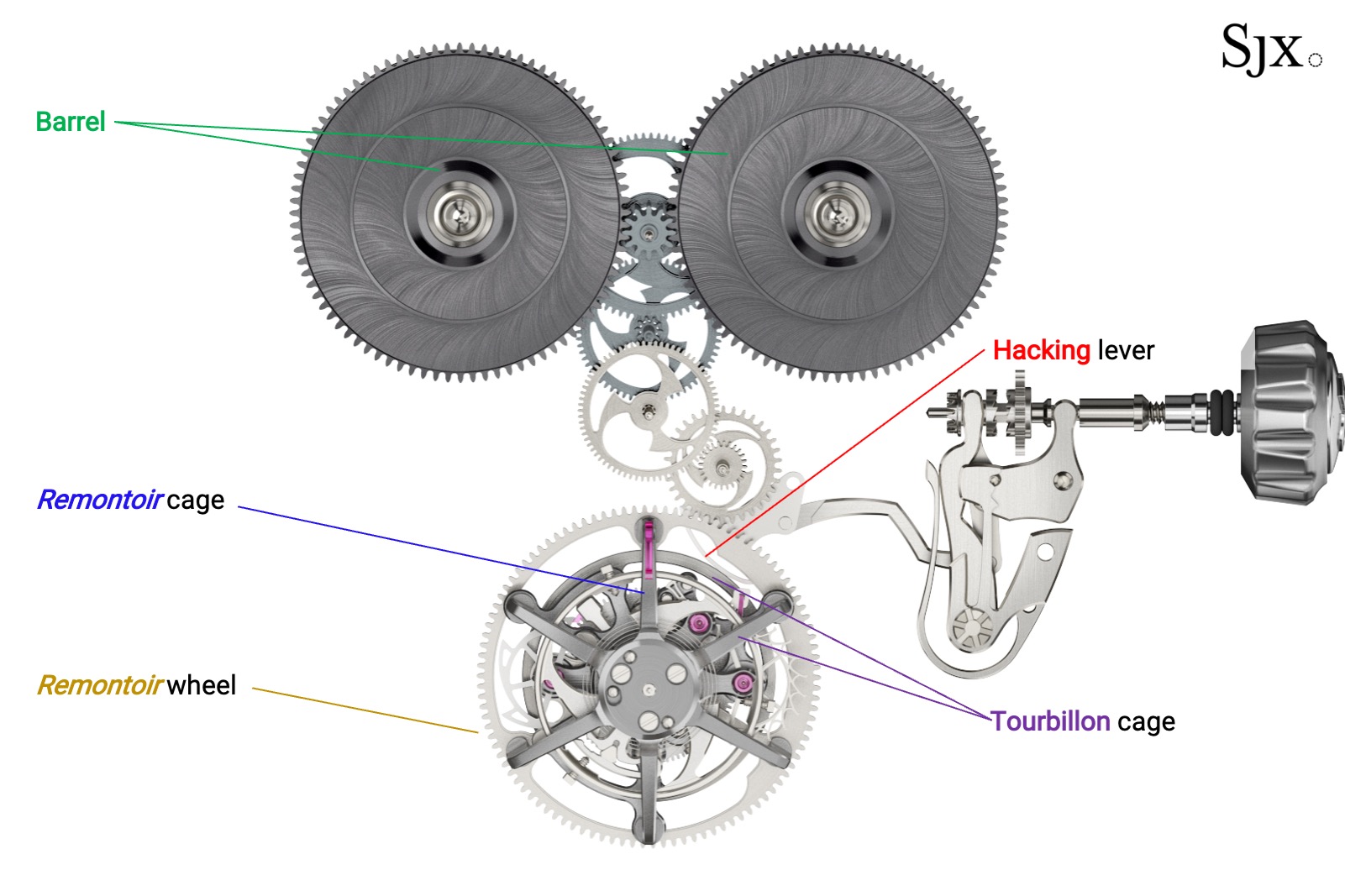

The fundamentals of the cal. 9ST1 are similar to that of a standard movement, which means it has barrels, gear train, and escapement. The major differences between the cal. 9ST1 and an ordinary movement lie at the end of the gear train, or more precisely at the fourth (or last) wheel that typically drives a seconds hand. Instead of a fourth wheel, the cal. 9ST1 has a remontoir wheel.

Power flows from the barrels through the gear train to the remontoir wheel, which is where it gets interesting. The remontoir acts like a typical fourth wheel, meaning the remontoir wheel makes a full revolution every minute. But unlike a conventional fourth wheel that moves forward in an almost-smooth motion, the remontoir wheel advances one step every second. As a result, it is actually a double-function complication.

The Kodo logically makes use of that. A three-armed remontoir bridge is fixed on the top of the remontoir wheel, allowing it to act as jumping seconds indicator, with the ruby mounted on one of the arms serving as the pointer. It’s worth mentioning that the wheel and bridge forms the entirety of a remontoir cage. In a typical tourbillon watch, the gear train drives the tourbillon cage, but here it drives the remontoir cage.

Since the remontoir cage sits where the tourbillon cage would normally be, the tourbillon has to fit within the remontoir cage. Remember also that the remontoir drives the tourbillon within it, but to understand the connection between the two, we have to start with how the remontoir works.

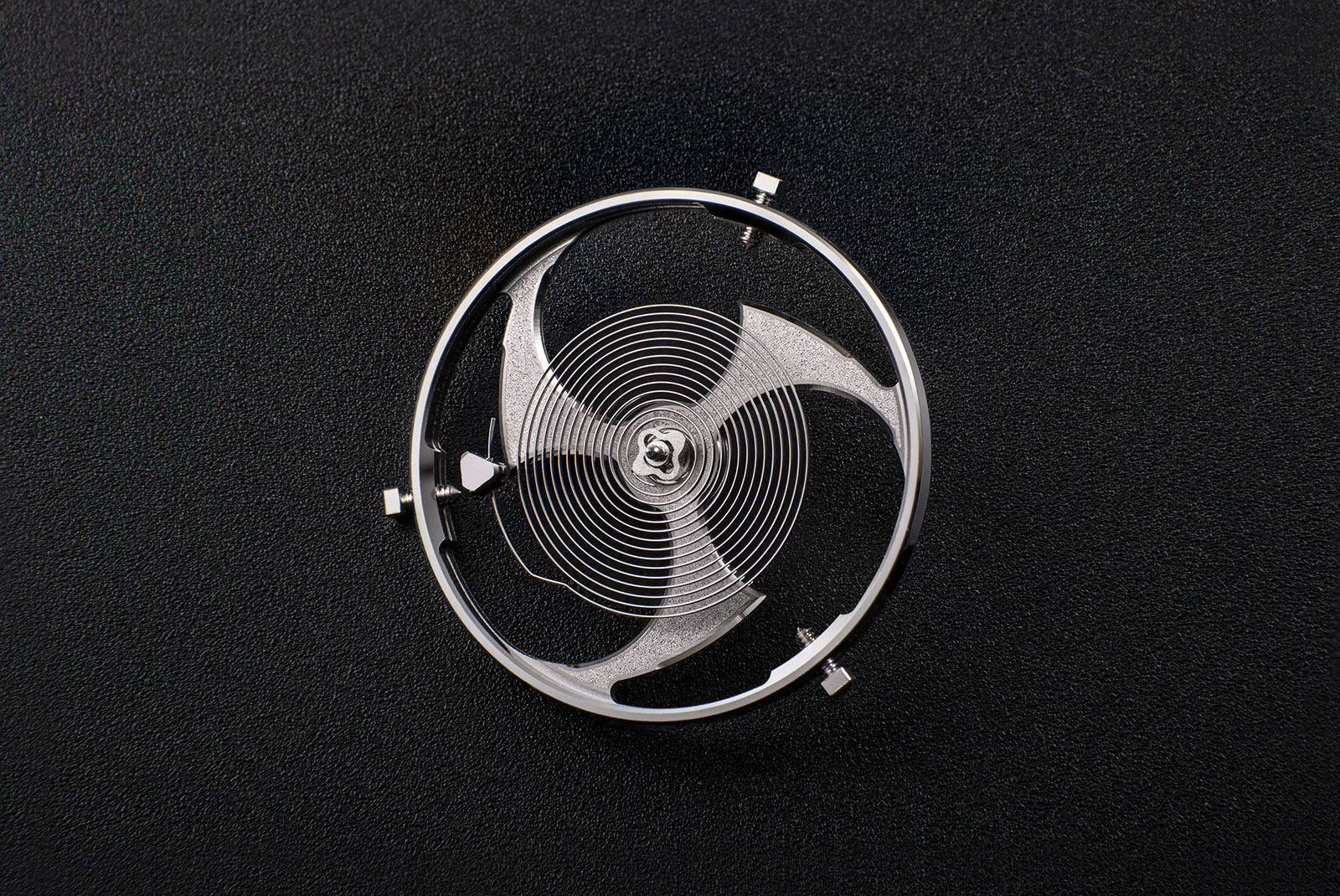

The key to the constant-force ability of a remontoir is the spiral buffer spring known as the remontoir spring. Essentially a tiny, secondary mainspring, the remontoir spring winds down quickly and as it does so propels the parts sitting above it.

Logically, the tourbillon cage sits directly above the remontoir spring. Each unwinding of the remontoir spring discharges a constant amount of energy, such that the tourbillon is driven by a consistent dose of power each second, thus making it a constant-force tourbillon. And because the remontoir spring is directly under the tourbillon cage – both rotate on the same axis – it is also a co-axial, constant-force tourbillon.

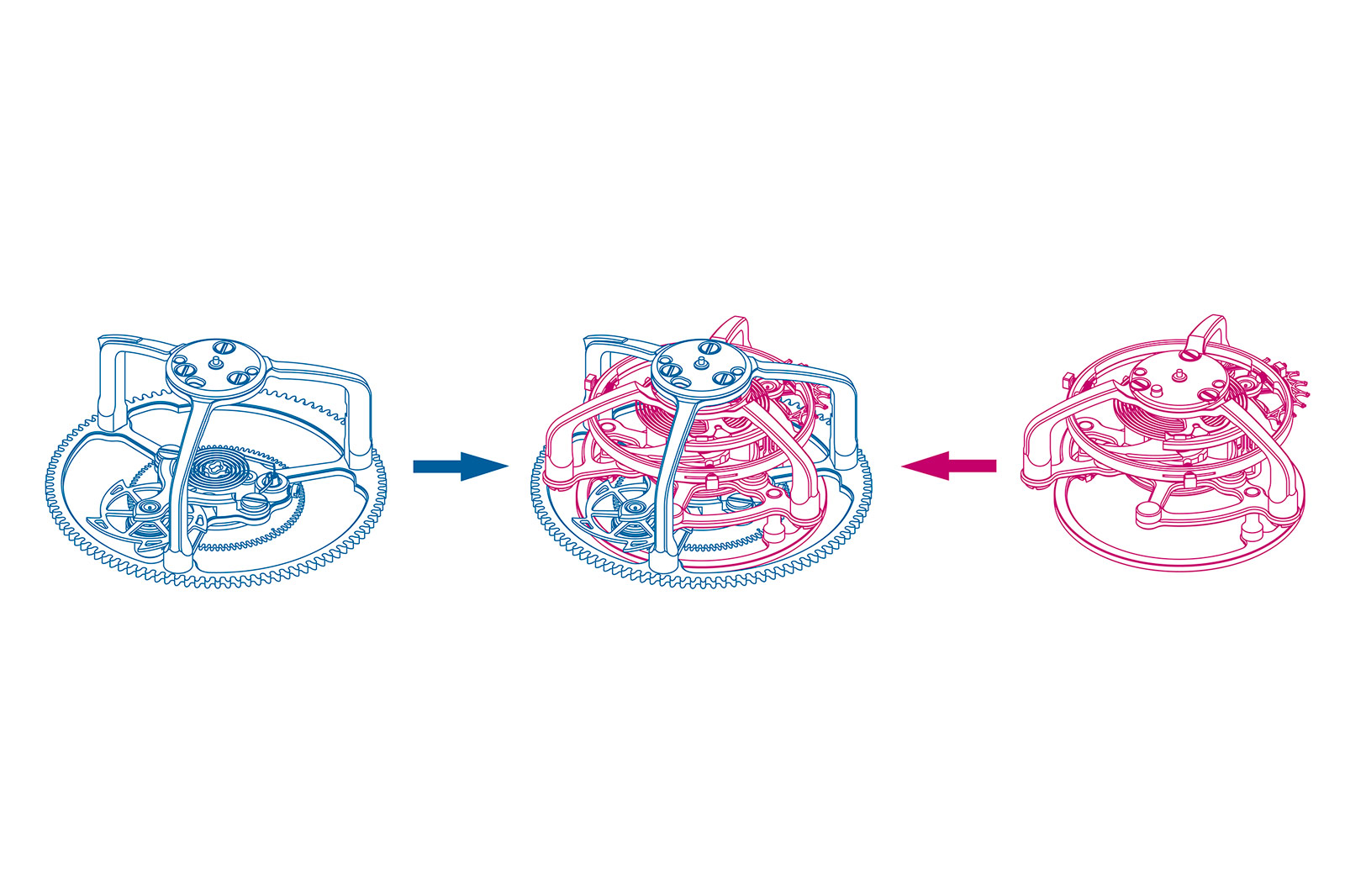

The tourbillon cage (red) is nested within the remontoir cage (blue)

How it really works

The basics of the cal. 9ST1 are clear: the gear train ends with the remontoir, and the remontoir in turn drives the tourbillon. But it is a complicated and delicate system with much mechanical ingenuity to appreciate.

The fundamental element of the assembly is the tourbillon. Remember that it is a mechanism designed to complete one revolution every minute, during which the escape wheel, pallet fork, as well as the balance wheel are rotating along with the cage. This constantly changes the position of the balance wheel, thus averaging out errors induced by gravity.

The Kodo, however, adds a remontoir into the mix. Here tthe remontoir is locked in a feedback loop with the tourbillon. The remontoir spring, and hence the remontoir cage, releases in one-second steps in a process that’s regulated by the tourbillon. In other words, though the tourbillon is driven by the remontoir, it conversely controls the periodic release of the remontoir.

Both the tourbillon and remontoir are co-axial, a set up that eliminates the need for an intermediate wheel in between, which reduces power loss through friction.

The remontoir spring unwinds at a controlled rate that is dependent on the escapement within the tourbillon. If the escapement were absent, then the remontoir will release instantaneously instead of once every second.

The operation of the remontoir lies in the fact that it’s essentially a miniature mainspring with enough energy to drive the tourbillon for about one second. And that’s exactly why the remontoir is a constant-force mechanism – the spring delivers the same, small dose of energy to the escapement within the tourbillon, so collectively the remontoir and escapement form the constant-force tourbillon system.

Now that we understand how remontoir spring powers the tourbillon, it’s time to look at how the spring is recharged. Attached to the base of the tourbillon cage is a C-shaped steel ring with a protruding arm, which rotates along with the tourbillon cage.

At the end of the protruding arm is a synthetic ruby shaped like a pallet jewel. Next to it is a five-spoked, white ceramic wheel that is blocked by the pallet jewel of the arm. Together, they form a secondary escapement with the jewel acting as a blocking mechanism for the remontoir.

As the C-shaped ring rotates along with the tourbillon cage, the tip of the jewel slides past one tooth of the ceramic wheel, releasing the remontoir spring, allowing the remontoir cage to rotate forward one step, until the next tooth of the ceramic wheel contacts the pallet jewel. This takes place at one0second intervals – in other words, the remontoir is released after the tourbillon cage advances six degrees clockwise, which is eight “ticks” of the 4 Hz escapement.

As mentioned earlier, since the remontoir cage is constructed to recharge every second, its motion allows it to function as a jumping seconds indicator. This double function is common for such remontoir mechanisms, but the Kodo executes the idea in a unique manner as the remontoir cage is co-axial with the tourbillon cage.

Other interesting features

While the constant-force mechanism and tourbillon are the heading features of the Kodo’s cal. 9ST1, it actually incorporates several interesting – and practical – features.

One is the hacking function of the tourbillon that’s constructed in an unusual way. A conventional tourbillon-hacking mechanism – a rare complication for a tourbillon – typically relies on a flexible stop lever that contacts the balance wheel and halts everything instantaneously.

But the Kodo has the hacking lever contacting the lower ring of the tourbillon cage, which allows the balance wheel within the cage to oscillate for a few more cycles before it eventually stops.

On its face, this method is not the most impressive from a visual perspective since the tourbillon does not stop instantaneously. However, stopping the carriage is an uncommon approach because of its complexity; stopping the cage abruptly while allowing the balance to oscillate can potentially damage the escapement.

Implementing this hacking mechanism required finesse in both design and execution. According to Mr Kawauchiya, “The magnitude of the force applied to the carriage during hacking, however, is actually very small because the frictional force required to stop the carriage rotation is calculated and the spring force of the lever is designed to stop the carriage with the minimum necessary safety ratio.”

“Therefore, the force used to hacking the carriage does not damage any components,” he explains, “However, since the spring force of the lever must be strictly controlled, the spring is slightly bent by hand during assembly to fine-tune the spring force… The amount of movement of the spring tip is so tiny that it requires very delicate work.”

“Kodo stops the rotation of the tourbillon carriage by moving the spring tangentially to the carriage, rather than radially – when the spring is disengaged, a slight counterclockwise rotational force is applied to the carriage to ensure the restarting of the tourbillon,” continues Mr awauchiya, “This method is an application of a mechanism that was originally found in calibre 45 and the stopwatch developed by Seiko for the 1964 Tokyo Olympics.”

Another notable feature is the grand sonnerie-style winding click, which is symmetrical just like the twin barrels that flank the click. A classical and elegant approach to the winding click, the grand sonnerie-style winding click is rarely found in modern watchmaking and is being used for the first time by Grand Seiko.

(A detailed explanation of the grand sonnerie-style winding click can be found here.)

The grand sonnerie-style (right), with one of the sharply open-worked barrel ratchet wheels just adjacent

As with all of the Kodo, the grand sonnerie-style winding click was the result of purposeful design. “There are three reasons for adopting the grand sonnerie-style winding click,” explains Mr Kawauchiya, “First, for functional reasons, a winding click that can distribute the force between two click springs is suitable for the high torque of the twin barrels in the Kodo.”

“Secondly, Kodo is all about symmetrical layout of the movement as a whole, and it was ideal for the intermediate wheel connecting the two ratchet wheels to integrate the function of a click,” he continues. “Lastly, as you pointed out, we believe that the grand sonnerie-style winding click is both traditional and very beautiful, and we wanted to try this style, which has never been used by Seiko or Grand Seiko before.”

Also apparent is the fact that the barrels are designed to slip to prevent overwinding, a feature borrowed from automatic movements. This can be deduced visually as there is a lack of a distinct recoil mechanism on the ratchet wheel click – a feature otherwise required to prevent the high torque spike from a fully-wound barrel.

Mr Kawauchiya mentions there is an additional benefit of a slipping mainspring relating to efficiency: “It allows us to design a smaller amount of recoil for the ratchet, which means minimum rotation of the winding stem and crown is needed to activate the winding click, thereby reducing loss of energy due to recoil during winding.”

“Since the movement has two barrels to be wound by hand, we designed it to minimise the loss during winding,” Mr Kawauchiya continues, “At the same time, we wanted to create a pleasant winding sound and clicking feel, so we changed the design of the click found in the T0 [concept movement] to the grande sonnerie-style in the Kodo.”

Accuracy

Since the cal. 9ST1 has not one but two mechanisms for precision timekeeping, it is natural to compare its performance with other GS movements, especially the brand’s historical pinnacle of timekeeping achievement, V.F.A. or “Very Fine Adjusted”.

Vintage V.F.A movements were accurate to within a minute per month, while modern V.F.A. movements are regulated to achieve a maximum daily deviation of +3/-1 seconds. On the other hand, the Kodo accurate to +5/-3 seconds a day. Why the disparity?

I discussed this with GS representatives at W&W. The designers of the cal. 9ST1, including Mr Kawauchiya, explained the rationale with two key reasons.

The first lies with the regulating process behind each type of movement. Regulating a V.F.A. movement and cal. 9ST1 of the Kodo are entirely different processes.

A V.F.A. movement is essentially a top-performing version of a standard calibre like the cal. 9S85, which means it is selected from a large pool of already-regulated standards movements and then further regulated by a specially-trained watchmaker to conform to an even tighter standard.

But the same approach is impossible with the cal. 9ST1, since only two dozen examples of the movement will be made – and that includes prototypes. There are simply not enough of them.

The second, and perhaps more crucial, reason is the length of testing. The mean daily rate of the Kodo is measured twice during during testing, at the 24- and 48-hour marks. In contrast, a V.F.A. movement is tested only after 24 hours of running.

Accuracy is measured over a longer period for the Kodo, which is logical considering the movement incorporates a constant-force mechanism that is meant to optimise timekeeping over prolonged periods. Even though the Kodo is regulated to +5/-3 seconds a day like a standard GS movement, it is more impressive because of the difficulty in achieving the same accuracy over a duration that’s twice as long as the standard testing period.

“Regarding Kodo, our priority is different from that of V.F.A.,” says Keiko Naruse, a senior marketing manager at Seiko Watch Corporation, “Kodo aims to provide the stable accuracy for longer periods thanks to constant force and tourbillon.”

She adds, “Theoretically, a V.F.A.-accurate watch with constant force and tourbillon could be made by following the V.F.A. approach, but when determining the product specifications for Kodo, we prioritised stability over a long period of time in consideration of actual use for the wearer.”

That aside, I believe that it is far more difficult to regulate a movement as complicated as the cal. 9ST1 as compared to an ordinary movement. The extra parts at the end of the gear train in the cal. 9ST1 might, rather counterintuitively, hinder the pursuit better accuracy due to friction, but there’s no question that the cal. 9ST1 has the upper hand over its simpler brethren over longer periods thanks to the remontoir.

Concluding thoughts

Intriguingly, Grand Seiko reports that the Kodo runs within +5/-1 seconds per day in real life testing on a wrist, as opposed to +10/-1 seconds per day for a generic 4 Hz movement (and +8/-1 seconds per day for a generic high-beat, 5 Hz movement.

With that in mind, it is fair to conclude that GS is being extremely conservative in the accuracy promises being made for the Kodo. If I ever lived out a fantasy and had the Kodo on the wrist for a few weeks, I am certain it would keep time much better than the stated rating.

With that mind, it would probably have been more effective to announce a superior timekeeping standard for the Kodo, at least from a marketing perspective. That said, relatively conservative marketing claims are typical of GS’s modest approach despite its very fine products. And who knows, perhaps a more elaborate testing regime is in the pipeline.

Still, leaving aside the numbers, the Kodo is an impressive and highly complex object. It is clear that every single element of the movement as well as the case has been carefully considered and then executed to a high level. Even thought GS has never produced a watch like this before, it has managed to surpass even some of the most experienced competition.

Key facts and price

Grand Seiko Kodo Constant-Force Tourbillon

Ref. SLGT003

Diameter: 43.8 mm

Height: 12.9 mm

Material: 950 platinum and Brilliant Hard Titanium

Crystal: Sapphire

Water resistance: 10 bar

Movement: Cal. 9ST1

Functions: Hours, minutes, dead-beat seconds, tourbillon with constant-force mechanism

Winding: Manual wind

Frequency: 28,800 vibrations per hour (4 Hz)

Power reserve: 72 hours

Strap: Calfskin strap with platinum folding buckle, and additional double-sided crocodile strap

Limited edition: 20 pieces

Availability: Starting October 2022 from Grand Seiko’s retailers and boutiques

Price: US$350,000; or 40 million Japanese yen before tax

For more, visit grand-seiko.com.

Back to top.